Betting the Farm: The Story Behind the M1A

Everyone who knows the name Springfield Armory knows the M1A. Hailing from an era of manufacturing when rifles were constructed of wood and steel and based upon the revered U.S. Military M14 rifle with a lineage connected to the iconic M1 Garand rifle, the M1A represents a fascinating intersection of modern performance and classic design.

The 7.62x51mm NATO (.308 Win.) M14 rifle was adopted as the United States’ primary service rifle in the late 1950s, but ultimately phased out soon thereafter in the mid-1960s (in favor of the then-new M16 in 5.56x45mm NATO). However, its appeal — and usefulness — far outlived its officially short lifespan.

In fact, the M14 continued to serve in specialized roles well past its official retirement. Its impressive power and downrange performance gave it a new lease on life in the era of the Global War on Terror in far-flung regions of the world in the hands of U.S. soldiers and Marines. In a way, its path was similar to that of another old warhorse, the 1911 pistol, which is still serving in limited roles well past its official retirement.

While the path the select-fire M14 rifle followed in the hands of the U.S. Military is a fascinating one, another version of the design took a different journey. That sibling’s path would lead it into the eager hands of civilian shooters who recognize the classic appeal of the wood and steel rifle. This journey, beginning 50 years ago this year, would be shepherded by a man named Dennis Reese.

A New Foundation

Mr. Reese, CEO and owner of Springfield Armory, has a deep connection with the M1A design. I recently had an opportunity to sit down with him and learn more about the story behind the M1A rifle.

Early into the conversation, I learned that firearms have long been a passion for the Reese family.

“My father, Bob Reese, would buy demilitarized surplus firearms as scrap iron from the Rock Island Arsenal that had been torch cut,” Dennis Reese explained to me. “Those demilitarized guns still had valuable parts that could be removed and sold to surplus dealers and manufacturers. There were BARs, M1 and M2 Carbines, M1 Garands, Thompson submachine guns, 1911 pistols, 1903 Springfields, and more,” he continued.

Reese explained to me that he and his two younger brothers, Dave and Tom, helped their father on these projects. Their work proved to be very successful, with a great deal of demand for these firearms parts. In fact, it grew to the point where their father opened Reese Surplus, Inc., a surplus store in Geneseo, Illinois. As the business grew, he developed connections with dealers and firearms manufacturers around the country — one of which would prove to be extremely fortuitous for fans of the M1A.

Diverging Path

How did selling gun parts lead to producing a civilian-legal, semi-automatic variant of the M14 rifle?

“When I was 19 years old, I had put in two years of college working toward a degree as an electronics engineer. I had decided it was just not for me,” he told me. “I came home and asked myself, ‘Where am I going to go from here?’.”

Reese, having grown up around firearms, was fascinated with them. He loved shooting and hunting. So, he spoke with his father about it and decided he wanted to make working with firearms his living.

His father mentioned that there was a company down in Texas that he had done some business with, and they owed him some money. He was going to go down and see about settling up with them and asked Dennis if he wanted to go with him.

Dennis and his father traveled to San Antonio, Texas, to negotiate a trade of product to settle the debt. What they discovered was, in addition to a lot of general surplus parts, a great deal of M14 inventory. The negotiating moved beyond the debt discussion to them seriously considering making an offer to buy all of it.

“I remember my father calling my mother and telling her that he thought the business had some potential. ‘Are you comfortable with us going bigger into this?’, I heard him ask her. Soon, my father and I were discussing what it would take to purchase the company itself,” Dennis Reese explained to me.

So, a trip that started as a simple effort to settle a debt turned into a life-changing opportunity for Dennis. In fact, the opportunity was so great that, in order to fund the purchase, Reese’s parents chose to mortgage the family farm.

“My parents risked everything on their 19-year-old son and his younger brothers in this new venture,” Reese said to me.

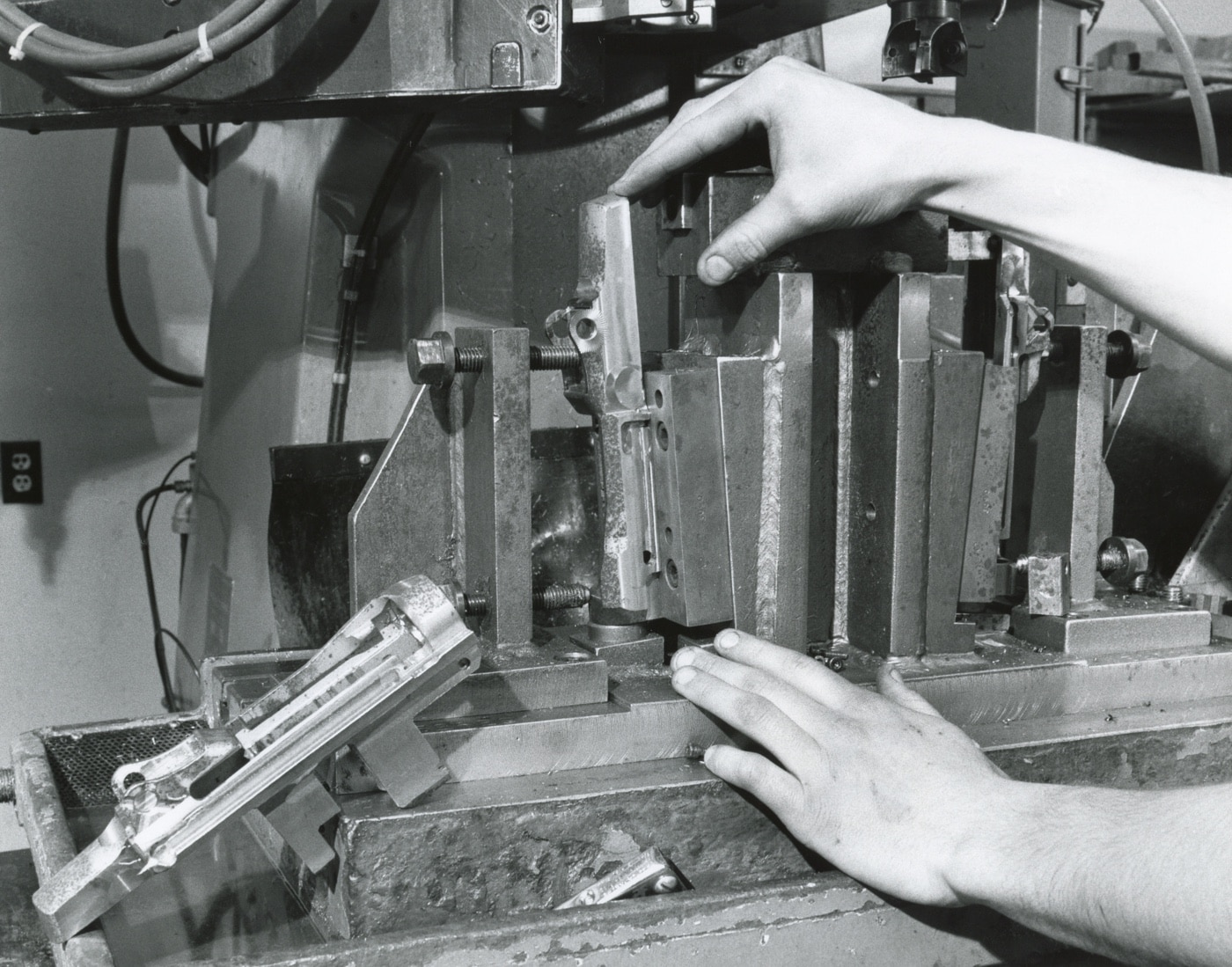

Once the purchase was done, Reese and his father filled up two semi-truck trailers with inventory, office and machining equipment, etc. and took it all back home. They set up shop in downtown Geneseo at 218 South State St. in what was formerly the “Sunshine Snack Bar,” a little diner that had closed. Reese set up shop and began building M1A rifles from the surplus M14 parts they had acquired in the purchase.

“Dad would come in and work part of the day in addition to his farm duties, and I was there all day working,” Reese told me. “My brothers were in high school at the time but would come in and work after school. This was truly a family business and a family effort. My family had literally bet the farm on this effort.”

Moving Forward

If the story ended here with Dennis Reese and his family building classic M1A rifles — cottage industry-style — in that diner, it would make for a fascinating example of the benefits of hard work and the realization of the American Dream. But, the story did not end there, and is one that continues on through to today.

Let’s be frank — the M1A has a naturally “retro” appeal to it. As noted, it’s a design from an era when rifles were made of wood and steel. While its manufacturing may have begun with an equally old-fashioned approach, the Springfield Armory M1A of today represents a totally new and modern method of manufacturing and design.

Today, the M1A — along with numerous other Springfield firearms — is manufactured in Springfield Armory’s state-of-the-art manufacturing facility in Geneseo, Illinois. While the original process of manufacturing the M1A begun 50 years ago produced a very high-quality rifle, it was also done in a system with numerous operations run on a variety of machines — some custom-built and more than 50 years old.

“Throughout the entire manufacturing process, from raw steel to final assembly, we have developed a modern process with a culture of quality to ensure that we uphold the standards set by Mr. Reese back at the launch of the M1A rifle in 1974,” said Christopher Baumbach, Engineering Program Manager, Machining, as we discussed the manufacturing processes of the M1A rifle today, and in particular the receiver.

He went on to explain to me that Springfield has implemented an automated machining cell that uses the latest manufacturing technology. The cell uses 5-axis machining, a Fanuc Robot on a “7th axis rail”, hydraulic fixturing and advanced tool monitoring. This allowed them to reduce the number of machining operations and ensure consistency throughout the process. He also noted that they have improved the heat-treating process by going to an advanced vacuum carburizing system.

Yes, this was all as bewildering to me as it likely is to any of you other non-engineers out there. When I asked Mr. Baumbach if he could translate this into layman’s terms for me, he explained that they adapted the manufacturing process to take advantage of some of today’s most advanced technology. The result is a product that offers the appeal of the classic 20th century design, but with levels of precision and quality that represent 21st century capabilities. Basically, it makes the M1A a rifle with one foot in the past, and one in the future.

Where It Stands

Springfield Armory clearly understands the appeal of the M1A rifle, and the shooters who appreciate it. Today, you can purchase an M1A Standard Issue .308 rifle extremely similar to the original M1A rifle the Reese family built in that tiny diner 50 years ago — but one that harnesses five decades of experience and technological advancement in manufacturing.

Beyond that, the M1A line has not been frozen in time since those early days, with many other variants now also available. For example, there is the M1A SOCOM 16 family of rifles that take the M1A design and sizes it down to an ultra-compact 16” gun with a redesigned gas system and advanced muzzle brake. For something a little longer but still quick-handling and compact, the M1A Scout Squad packs in an 18” barrel along with a forward scope mount and specially designed muzzle brake.

If you’re looking for even more options, there’s the M1A Loaded series of rifles. Offered in .308 as well as the 6.5 Creedmoor cartridge, the Loaded series features medium-weight premium air-gauged National Match barrels, National Match tuned triggers and more. The Loaded Precision variant adds in a customizable Archangel Precision Adjustable stock.

And lastly, there’s the recently released M1A 50th Anniversary Rifle, a limited-edition M1A commemorating the half-century mark of production for the revered semi-auto rifle. Be sure to read Will Dabbs’ full review of the M1A 50th Anniversary rifle here. Limited to only 1974 examples, this rifle comes with a beautiful custom wood display crate, a certificate of authenticity signed by Mr. Reese, and a host of accessories.

Conclusion

It’s hard to overstate how revered a design the M1A is. With half a century of production behind it and a very bright future ahead of it, the M1A was clearly worth the Reese family “betting the farm” on it. I know I’m thankful they did, and am sure all the M1A enthusiasts out there agree. Here’s to the next fifty years of the design!

Editor’s Note: Be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in!

Join the Discussion

Featured in this article

Read the full article here